Electric Car Design and Manufacturing

Electric Vehicle Manufacturing

Worked on designing and manufacturing both mechanical and electrical components of an electric car for the Urban category of the Shell Eco Marathon Competition. Built a fully electrically powered car that can go up to 40km/h with an interface that emphasizes efficiency.

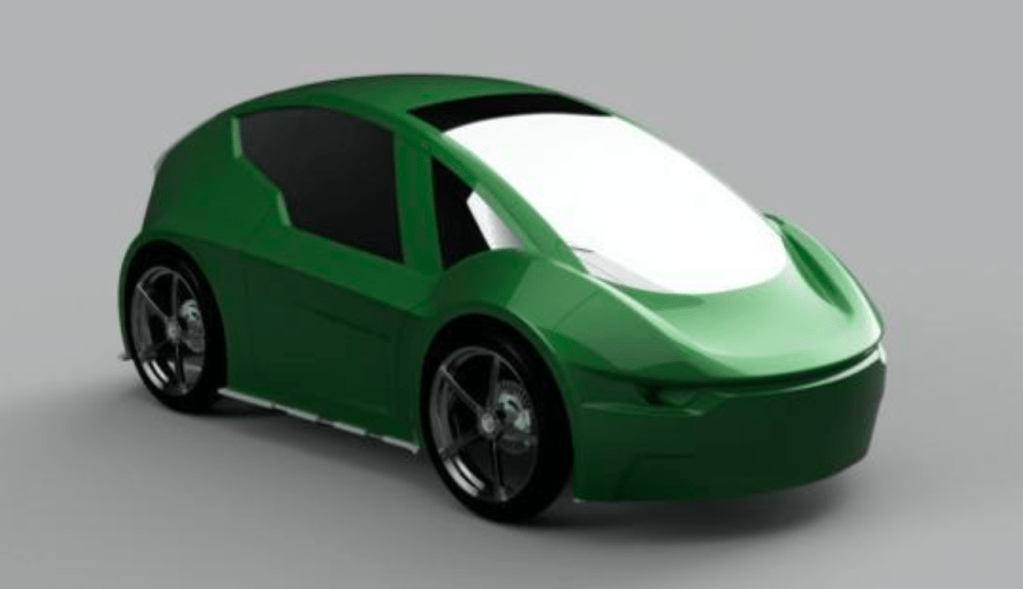

EV Body Designs & Manufacturing

Designed several prototypes for the car body and manufactured the most efficient design with carbon fiber via a molding process.

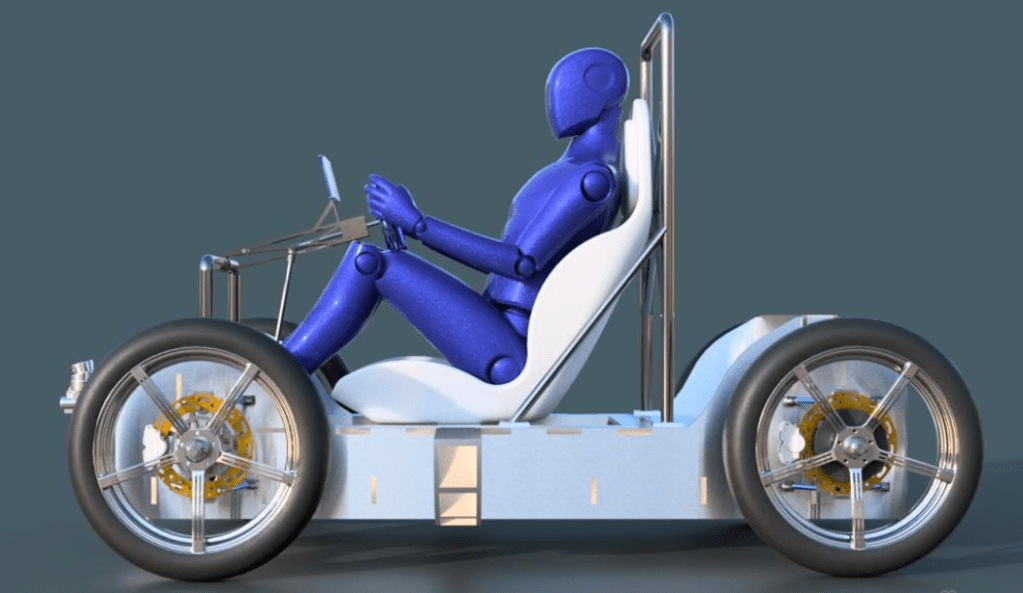

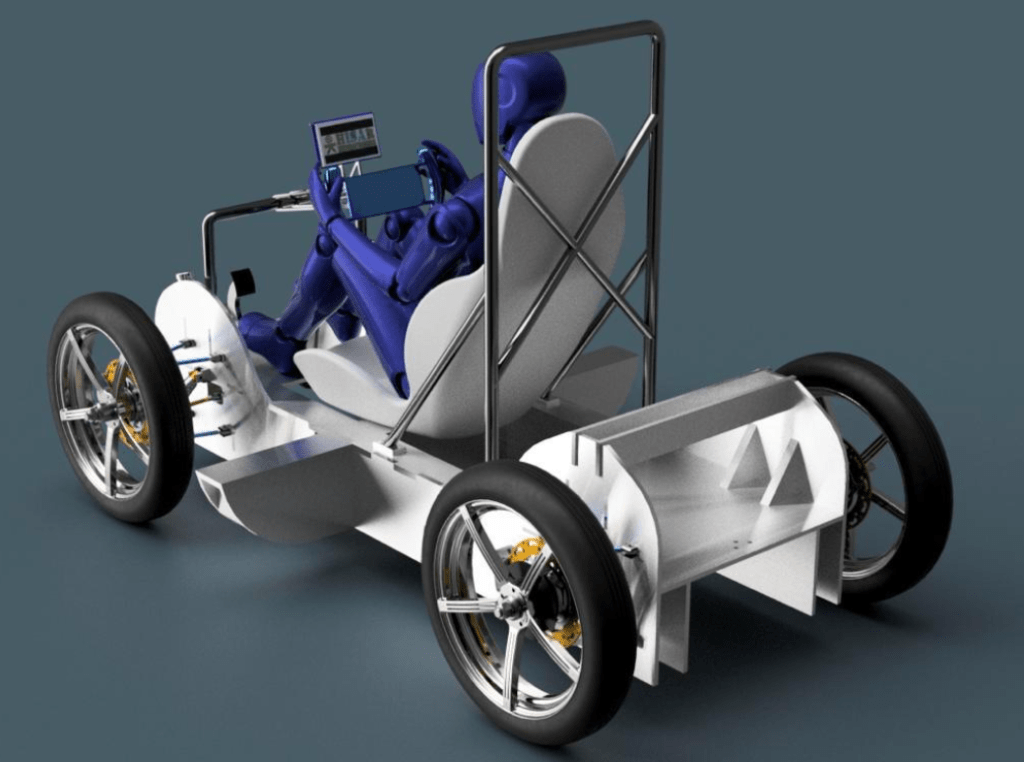

EV Chassis Designs & Manufacturing

Designed and built a chassis for the EV using carbon fiber for the body and steel for the roll cages.

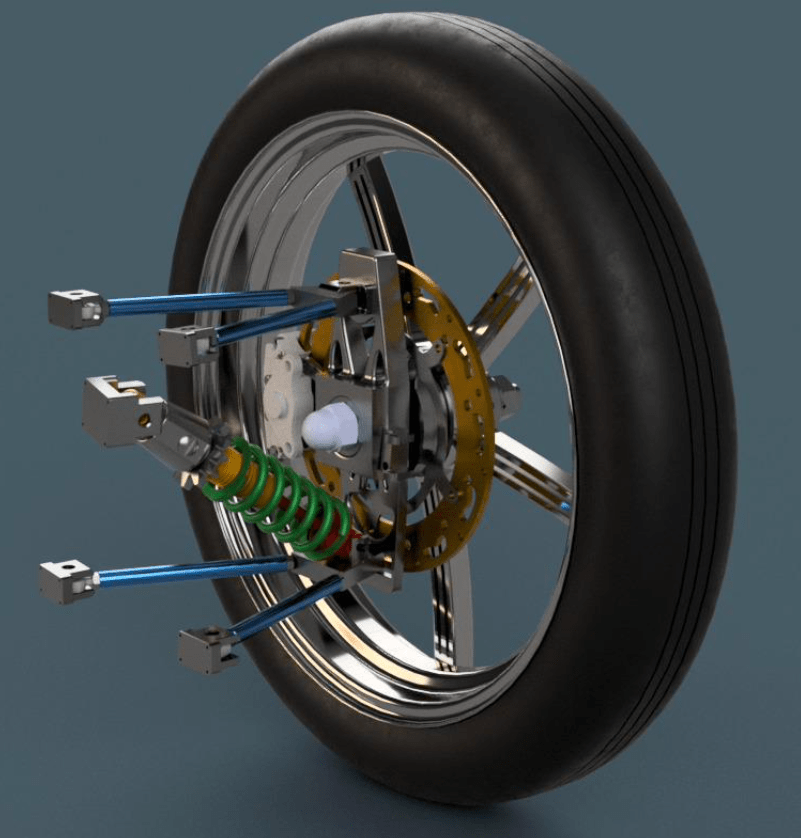

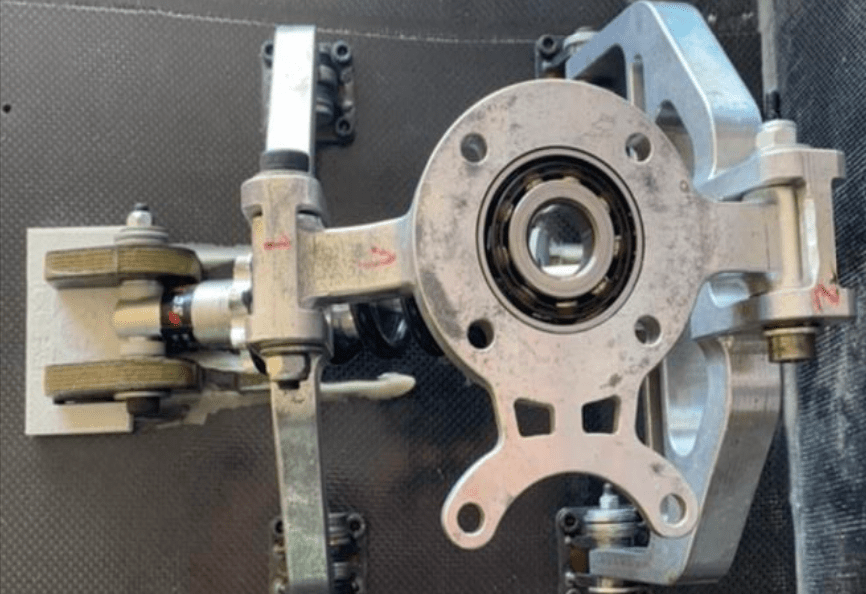

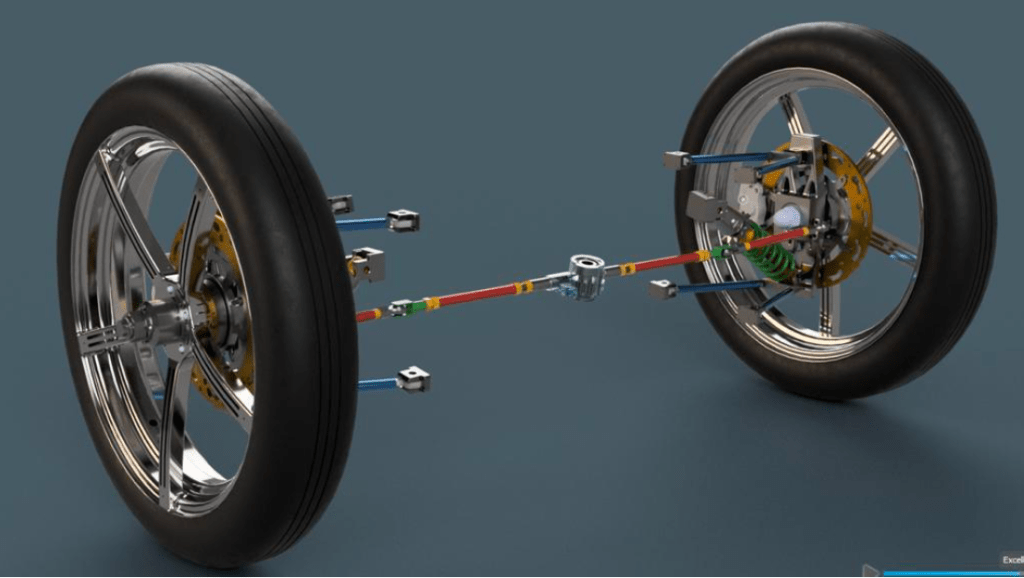

Double-Wishbone Suspension Geometry Design & Manufacturing

Designed and built a double-wishbone suspension geometry for both front and rear drive of the manufactured electric car. The design also includes the disk break structure which was utilized on the final design of the EV.

Steering Geometry Design

Designed and built the steering geometry that would connect the front wheels of the EV to the steering wheel after performing the necessary calculations.

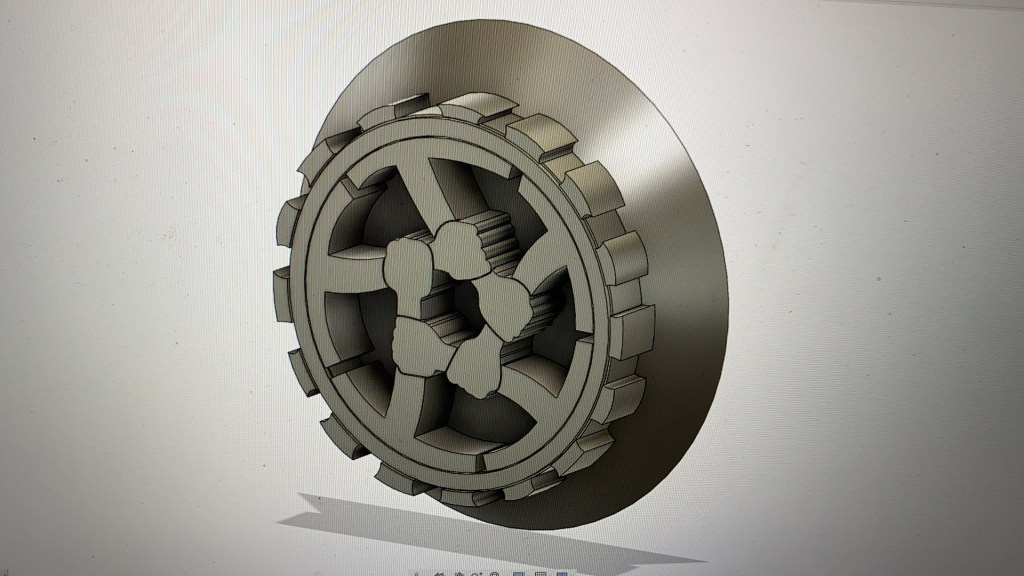

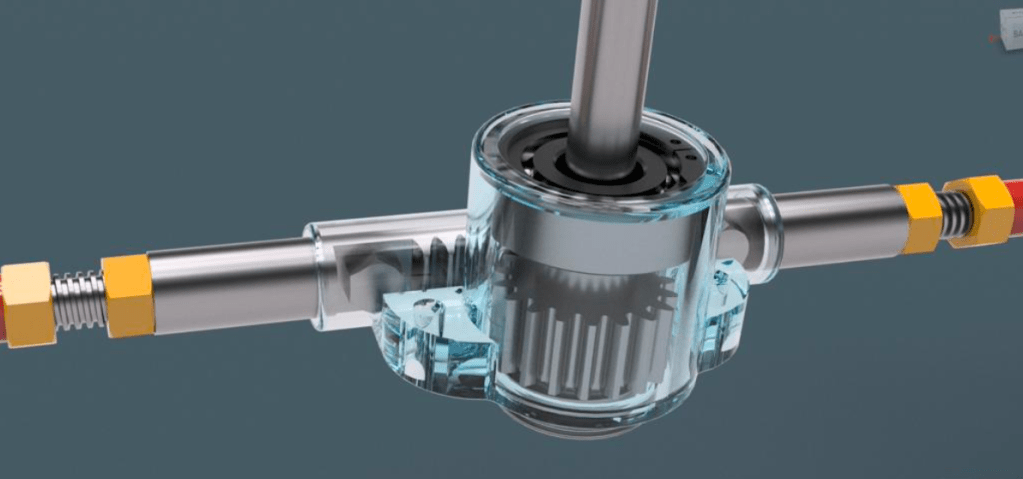

Rack-and-Pinion System Design

Designed and manufactured a rack-and-pinion system and its cover for the EV’s steering geometry based on the conducted calculations regarding the car’s turning radius.

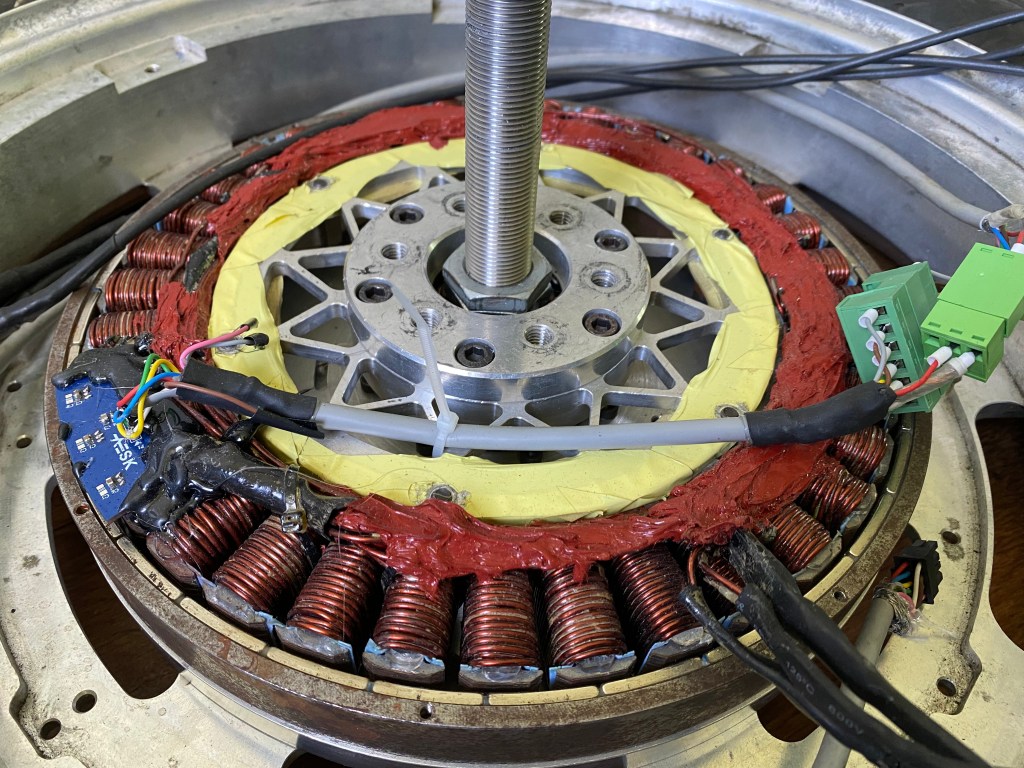

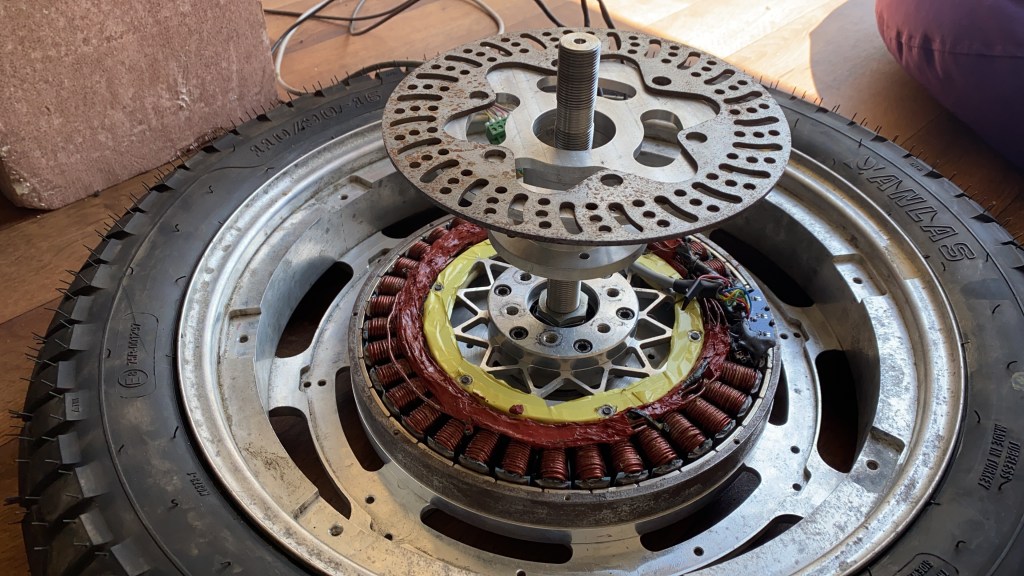

Hub Motor Assembly

Integrated a Hub Motor into the EV design while maintaining all project requirements, and analyzed functionality to prioritize efficiency.

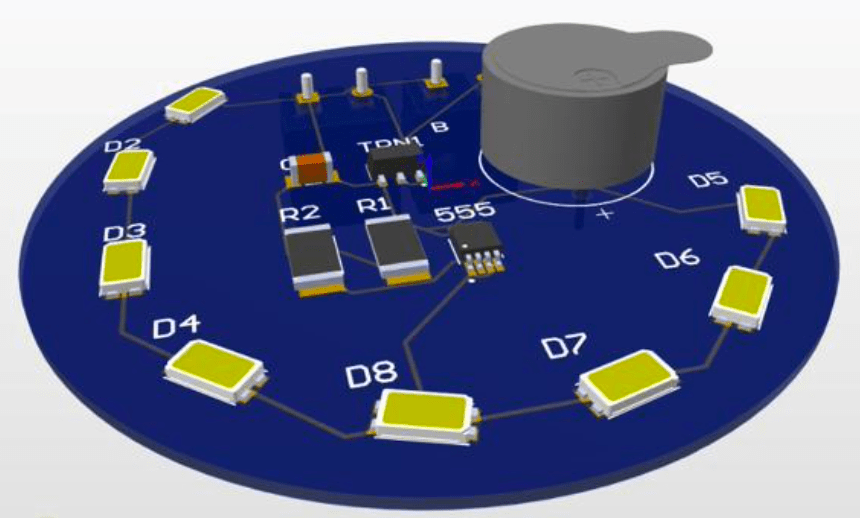

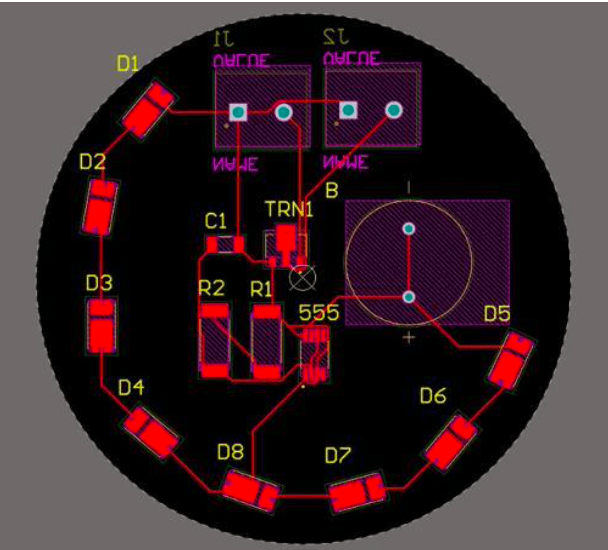

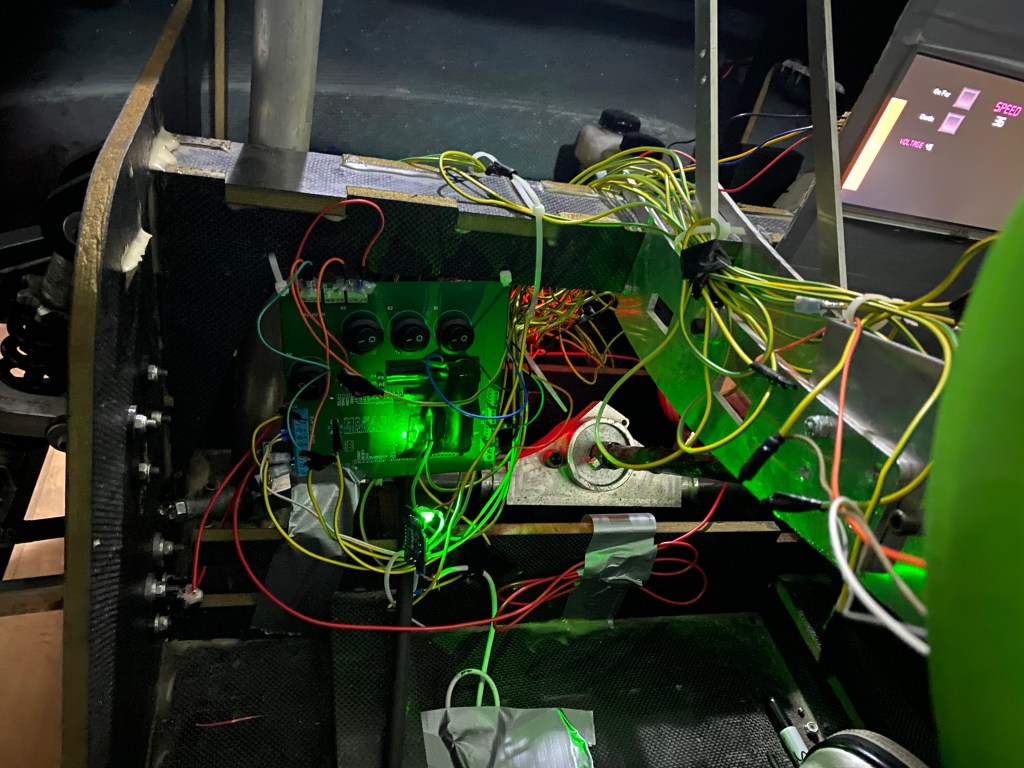

VCU & Car Headlights PCB Designs

Assisted the design and assembly of printed circuit boards for the manufactured EV’s Vehicle Control Unit and the headlight control system.

Wiring and Electronics

Electronic components were integrated into the car body. The wiring methods and electronic equipment placements were later optimized for driver comfort and safety.

3D Printed Additions

Designed and printed certain features of the car in order to make the car more aesthetically appealing.